Quality Assurance :

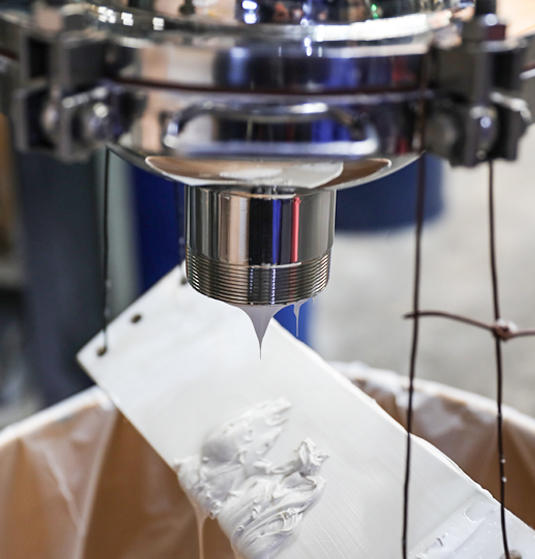

We have our own testing lab and the most advanced and complete inspection equipment,which can ensure the quality of the products.

| Projects | Technical specifications | Test Results | |

| Sag,mm | Vertical placement | ≤3 | 0 |

| Horizontal placement | No deformation | No deformation | |

| Application period,20min,s | ≤10 | 1.9 | |

| Surface drying time, h | ≤3 | 1.2 | |

| Hardness, Shore A | 20 〜60 | 51 | |

| Aging hot | Thermal weight loss,% | ≤10 | 2 |

| cracked | no | no | |

| Chalking | no | no | |

| Tensile bonding 23℃ | Tensile bond strength,Mpa | ≥0.60 | 1.12 |

| Elongation at maximum tensile strength,% | ≥100 | 117 | |

| Bond damage area, % | ≤5 | 0 | |

| Tensile adhesion 90℃ | Tensile bond strength,MPa | ≥0.45 | 0.74 |

| Bond damage area, % | ≤5 | 0 | |

| Tensile adhesion -30℃ | Tensile bond strength,MPa | ≥0.45 | 1.66 |

| Bond damage area, % | ≤5 | 0 | |

| After water-UV light exposure | Tensile bond strength,MPa | ≥0.45 | 0.77 |

| Bond damage area, % | ≤5 | 1 | |

As China Manufacturers of Silicone Sealant for Metal, Automotive and OEM Two Component Structural Silicone Sealant Factory, Jiangsu Runtai Sealant Industry Co., Ltd. established in year 2001, is committed to becoming the best partner in the field of silicone sealant industry under the principle of credit management, brand reputation, ecological and environmental protection, and high quality and good price. Located in Zhangjiagang, Jiangsu province, we are a professional enterprise engaged in the production of environmentally friendly decorative building materials, whose main products are numerous OEM color silicone sealant, polysulfide sealant, butyl rubber,etc. The products are widely used in construction engineering, curtain wall structural assembly and sealing, insulating glass processing, indoor and outdoor decoration, etc. We have an area of 28000 square meters with a production area of 25000 square meters and office area of 3000 square meters. Our company is in the hinterland of the Yangtze River Delta and near to Shanghai, Wuxi, Suzhou, Nanjing, enjoying convenient traffic. We have twenty production lines with an annual output capacity of over 30000 tons. With very advanced production equipment and improved technology, we have realized full automated production.Our company has ISO9001/ISO14001 standard system, and is Production Identification Enterprise of Silicone Structural Sealant by China Construction Metal Structure Association. We supply Two Component Structural Silicone Sealant Wholesale, our products are rated as Green Building Materials Products. Some series of our products are also rated as Featured Products by Construction Curtain Wall Industry Assessment.Since established, we have made stable sales network throughout domestic market and established long-term partner relationships with customers abroad. We will continue to innovate and develop, and adhere to the principle of good faith and quality, to be the first-class professional silicone sealant manufacturer in the world.

As Wholesale Two Component Structural Silicone Sealant Suppliers, we have our own production workshops and warehouses, equipped with complete production and quality inspection equipment.

We have our own testing lab and the most advanced and complete inspection equipment,which can ensure the quality of the products.

We have a strong R&D team,and we can develop and produce products according to the requirements or samples the customers offered.

We have 22 advanced production lines, ,which enable us can develop and produce a lot of products with different technology data, different colors, different packages.

We have professional sales team and technology team for after-sales.

Our annual production capacity is over 40000 tons,we can meet the needs of different customers with different purchase quantity.

We focus on developing high-quality products for top-end markets.Our products are in line with international standards.

Visit pre-registration, pass the badge directly to your hand, and have a better chance to win the pr...

At present, there should be many partners who are interested in the information of the top ten brand...

Beijing, China Economic Network, April 10: With the deepening of urbanization, the construction alum...

Beijing 2014-04-10 (China Commercial Telecom) - With the increasing promotion of real estate industr...